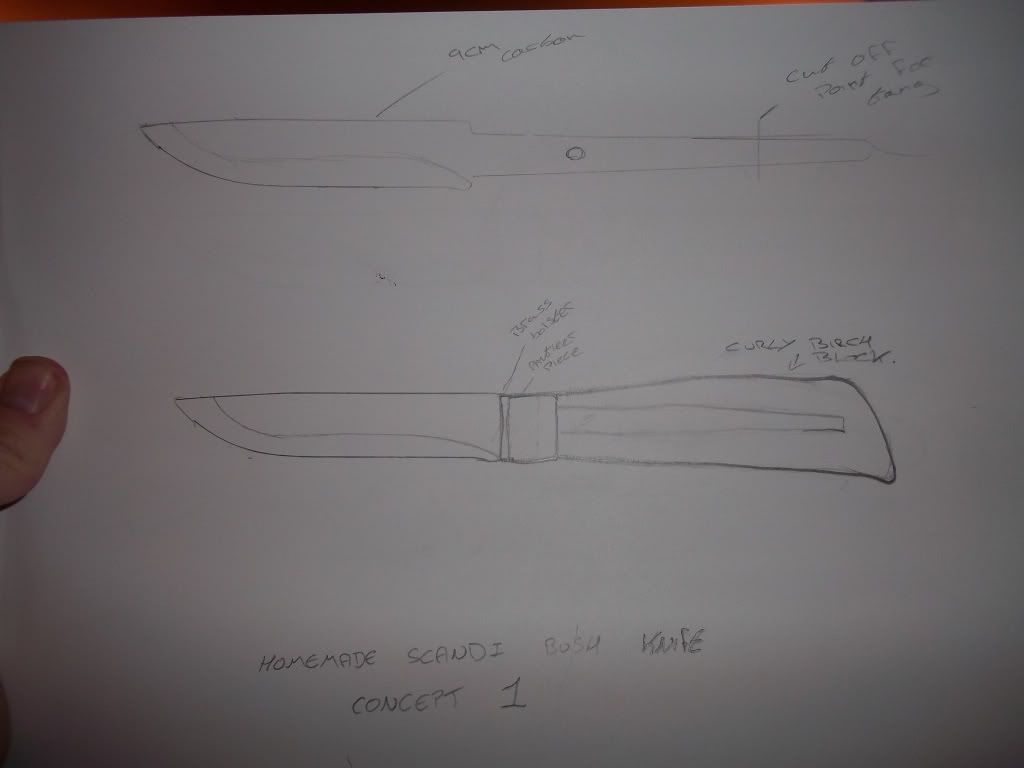

So i started with a very basic concept design. Don't worry if it doesnt turn out exactly the same as your drawing as you are going to change various things depending on numerous factors the grain, a cut to deep etc. On this drawing you will see i forgot to include the height of the antler and bolster and i didnt actually cut the tang down any but it worked as a rough shape for the handle which is all its needed for really.

Next you need to tape up the blade, this is pretty obvious you do this to both protect you and the blade. Then mark the antler with the hole from the bolster so you know where to drill the antler. Then file the tang down all the way except 20 mm at the top near the blade so that the bolster will easily go down the tang. When the bolster gets to that 20mm that was left unfiled take a rubber mallet and tap on the bolster until it is next to the blade, this ensures a good tight fit. Then drill 3 holes where you have marked on the anler and using needle files tidy it up so it fits easily on but dont force the antler. Then what i did this is not essential but later on it makes life alot easier when it comes to fitting the tang in the wood and that was take the tang and either file it into a point or use a belt grinder.

Next its time to mark out on the wood where you want the hole use the tang to mark out on the side the size of the hole needed then mark on the top of the wood and drill the holes needed. A tip i recommend is to mark the drill bit with the depth needed i made the mistake of not doing this and went too far and needed to get more wood.

Next you need to file the hole with needle files and file the tang if needed to get the knife to fit into the wood. Then mix up your araldite and get as much as possible in the hole, on the tang and between the bolster and antler then put a piece of wood on the tip of the blade and clamp in place and leave to dry for about 24 hours.

Draw a rought shape of the handle on the wood and then start to saw away as much excess as possible without cutting into where the handle will be you are just looking to get rid of some of the excess to make the filing a bit easier. Now begin to shape the handle using a rasp and a knife to whittle the smaller bits, this is a long and laborious process so dont be afraid to take a break if needed.

When you are happy enough with the shape of the handle its time to sand it. Its best to start off with a really course grit then down to a medium grit and a fine and then an extra fine untill its as smooth as possible. The use of an electric sander makes this job alot quicker.

Now its time to give it a finish. I used some boiled linseed oil and the more you oil it the darker it will go. So wipe some oil on and leave for 5 mins or so and then wipe off the excess.

Now that we have the knife finished its time to start making the sheath. So let the leather soak in some warm water for 5 mins or so soften it enough to make it easy to work with. Make sure the blade has some tape on it to protect it from the water and put the inner sheath over the blade. Then wrap the leather around the knife and inner sheath and use some clips to hold the leather in place. Then using a fork mark out the holes that you want to pierce with your awl. Then you need to remove the knife and start to sew the sheath with a saddle stitch. Run your thread through some beeswax and tie a needle at each end of the thread. Then pierce a hole with the awl and start the first stitch, then pierce the second hole and do the second stitch and carry that process on untill the leather is sewed. (There is a good video on the saddle stitch here http://www.youtube.com/watch?v=9fHYcnrSie8)

Now What you need to do is to re-soak the leather in warm water. Then place the knife in the sheath and start to mould and form the leather around the inner sheath and knife. And pierce two holes to thread you leather through either for a belt loop or as i have done with some leather thonging to make a necklace. When you are happy enough with the forming process leave the sheath in a warm place for a couple of days to dry. Hopefully the tape has kept the water off the blade but if there is any rust it comes off easy enough with some steel wool.

And thats the knife finished. I'm going to use this now as my main bush knife just because i'v made it myself. This process has been really rewarding and i'v learned so much. I cant wait to start on another one as there are some various things i would do differently but all in all i'm extremely happy with the knife. And making the sheath i found to be very rewarding so i think i may start and dabble in some leatherwork in the future.